- Home

- Products

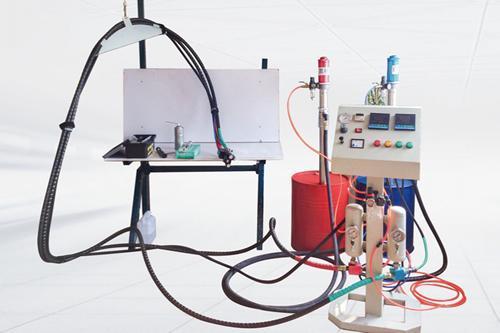

Lingxin is a dynamic enterprise that performs the design and production of polyurethane foam equipment. Our main products include our high pressure polyurethane foaming machine, low pressure polyurethane foaming machine and polyurethane elastomer casting machine, which can be used to produce PU products of varying hardness and elasticity.

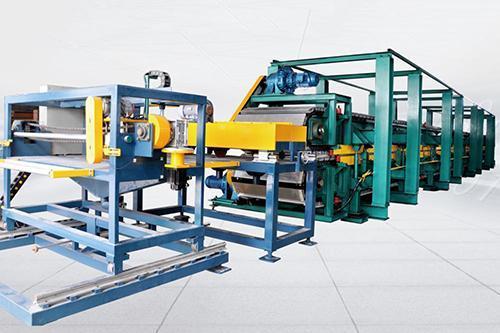

We have developed many different lines of production equipment and complete production lines for various polyurethane based products, such as polyurethane sealing strips, packing materials, ear plugs, insoles, car seats, and construction materials.

The main work flow of our polyurethane processing equipment is as follows.

The raw material tank is used for the storage and heating of polyhydric alcohol and polyisocyanate.

The two raw material tanks of the Lingxin high pressure foaming machine are equipped with high quality pressure valves. After the pressure achieves balance, the pressure valves will lock automatically to ensure it remains constant. There is a materials recycling function to prevent raw materials from crystallizing when the equipment is stopped.

The raw material tanks of our PU foaming machine and PU elastomer casting machine feature three-layer structures. The inner tank is produced using stainless steel. It is used for heating applications and is covered by the outermost insulation layer. This offers a safer, more energy efficient form of operation.

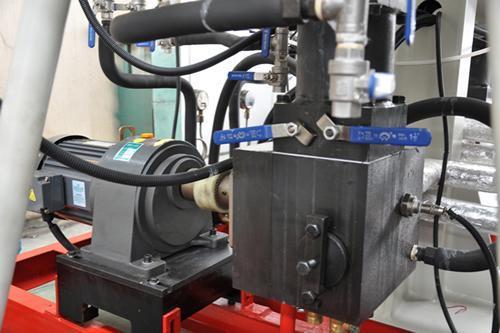

High-precision metering pumps are used for the metering of raw materials.

For example, the high-pressure PU foaming machine uses Gelanrex or Shanghai Linggang brand Plunger metering pumps. The measurement is accurate with stable operation capabilities.

The low-pressure PU foaming machine is equipped with a variable-frequency motor and a metering pump to regulate the flow and pressure of raw materials. The measurement accuracy error is within ±0.5-1%.

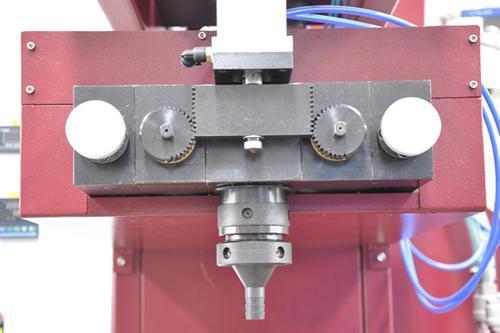

Lingxin polyurethane machines feature high-performance mixing devices to ensure uniform mixing of raw materials.

For example, a Korean SPU mixing head is used in the high-pressure PU foaming machine. Under high-pressure injection and impact, polyhydric alcohol and polyisocyanate raw materials are mixed. And there is no residual material left after use, meaning there is no need for regular cleaning and maintenance. The service life of the equipment is over 500,000 uses.

The low-pressure PU foaming machine comes equipped with an agitator blade in the head for the materials mixing and injection. Raw materials are evenly stirred and discharged with precision.

The mixing and stirring device of the PU elastomer casting machine uses a conical stirring blade. No bubbles are generated when stirring the raw materials, which results in a high quality finished product.

If you are engaged in or looking to begin in the production of polyurethane products, we can standard or customized PU production equipment according to your requirements with professional attitude and more than 10 years of industry experience.

Lingxin Polyurethane Machinery is manufacturing polyurethane processing equipment and machines, offering PU foaming machine line including material metering pump, high precision pumps, mixing head, and molding machines, and PU elastomer product machines for making PU elastomer products, PU elastomer processing system has several sections to fulfill elastomer products, the machines can be used to yield PU rigid foam, flexible foam, elastomer seal, PU shoe cushions and soles, PU plastic soft ear plugs, and many other which depended on the molding, Lingxin is a reliable and leading PU machine manufacturer, has provided hundreds of polyurethane equipment and machines with various functions to the global markets.